Product Category

Surface Grinding Jobs

Features:

- High Precision

- Multi-Axis Capability

- High-Speed Operation

- Modular Design

- Remote Monitoring

Dive into the realm of precision with an exploration of surface grinding machines. A surface grinder is a specialized machine tool designed to achieve critical dimensions and flawless surface finishes.

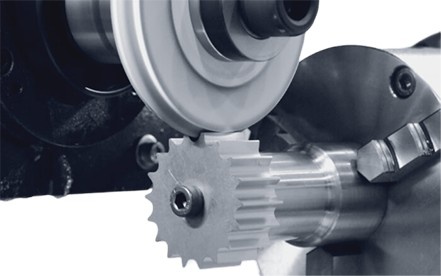

Surface grinding is a transformative finishing process that utilizes a rotating abrasive wheel to refine the flat surfaces of both metallic and non-metallic materials, resulting in a polished and dimensionally accurate end product. This process highlights the essential components of a surface grinding machine, including the abrasive wheel, which plays a crucial role in material removal; the chuck, which serves as a work-holding device; and the table, which is integral to achieving precise movement and positioning.

Our advanced surface grinding machines are equipped to handle both small and large components, ensuring that each piece meets the exact specifications required by our clients.

Applications:

- Tool and Die Manufacturing: Producing precision tools and dies that require exact dimensions and smooth surfaces.

- Spindle Components: Grinding spindle parts for machinery to achieve high precision and smooth operation.

- Fastener Production: Grinding bolts, screws, and other fasteners to meet strict dimensional tolerances and surface quality standards.

- Aerospace Components: Grinding parts used in aircraft engines and structural components to meet stringent aerospace specifications.