Product Category

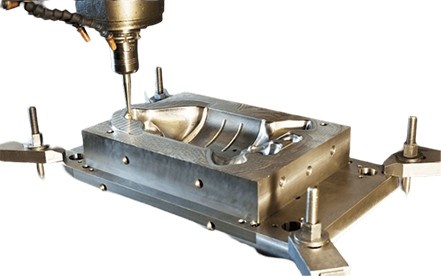

Plastic Injection Moulding

Features:

- Multi-Cavity Moulding

- Rapid Prototyping Capabilities

- Complex Assembly Parts

- Custom Color Matching

- In-Mould Labeling

We are dedicated to manufacturing high-quality plastic components for various industries. This method involves injecting molten plastic into custom-designed moulds to create parts with intricate shapes and high precision. Our expertise in plastic injection moulding ensures that we deliver reliable, durable, and aesthetically pleasing products that meet the specific demands of our clients.

We pride ourselves on our ability to provide comprehensive solutions, from the initial design phase to final production. Our advanced machinery and skilled technicians work together to ensure that every aspect of the plastic injection moulding process is optimized for efficiency, accuracy, and quality. By employing cutting-edge technology and adhering to best practices, we guarantee that our clients receive products that stand the test of time and perform reliably in their intended applications.

Applications:

- Consumer Products: Producing everyday plastic items such as kitchen utensils, personal care products, and household goods that require mass production and aesthetic appeal.

- Packaging Solutions: Manufacturing plastic containers, bottles, and closures for food and beverage products, ensuring compliance with health and safety regulations.

- Medical Devices: Creating sterile and precise plastic components for surgical instruments, diagnostic equipment, and drug delivery systems that demand strict quality control.

- Construction Materials: Producing plastic fittings, connectors, and components used in plumbing and HVAC systems, contributing to efficient and reliable infrastructure.