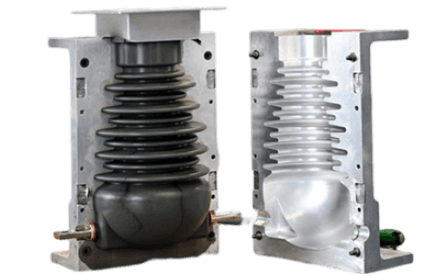

Product Category

Compression & Transfer Moulds

Features:

- High-Quality Materials

- Enhanced Material Flow

- Precise Temperature Control

- High Production Capacity

- Uniform Pressure Distribution

Trio Tech offers the design and manufacture of compression and transfer moulds, essential tools for shaping thermosetting plastics and rubber materials. The compression moulding process involves placing raw material into a heated mould cavity, where heat and pressure are applied to form the desired shape. Transfer moulding involves preheating the material before transferring it into the mould cavity, allowing for greater control over material flow and reduced waste.

Our compression and transfer moulds are engineered for precision, efficiency, and durability, making them suitable for various applications across multiple industries. We focus on delivering high-quality moulds that meet the specific needs of our clients, ensuring optimal performance in production processes.

Applications:

- Personal Care Products: Moulding parts for cosmetics and personal care items, including bottles, caps, and applicators, focusing on aesthetic appeal and functionality.

- Plumbing Fixtures: Creating moulded parts for plumbing applications, including fittings, valves, and pipes, which require resistance to chemicals and temperature variations.

- Oil and Gas: Transfer molded parts like seals and gaskets are crucial for ensuring the safety and functionality of equipment used in exploration, extraction, and processing.

- Furniture Components: Manufacturing moulded parts for office and home furniture, including chair bases, table legs, and decorative elements, ensuring aesthetic appeal and durability.