OUR PRODUCTS

At Trio Tech, we pride ourselves on delivering products that embody precision, durability, and innovation. Our comprehensive range of products is engineered to meet the highest standards, ensuring that you receive reliable solutions tailored to your industry needs. Whether you are in Oil & Gas, Marine, Plastics, Food Packaging, CNC Wirecut/EDM/Spark Erosion, etc., our products are designed to enhance your operations with unmatched quality and performance. As one of the leading oil field manufacturing companies, we ensure top-tier products for your specific requirements.

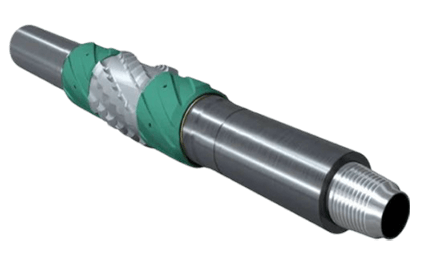

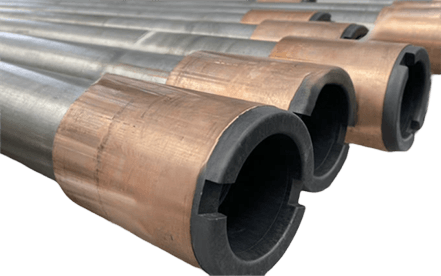

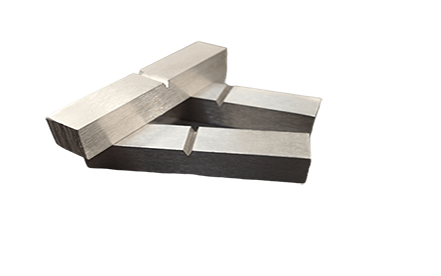

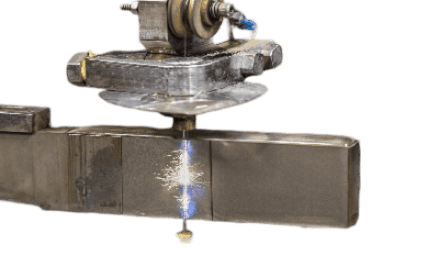

OIL & GAS PRODUCTS

Trio Tech Dies and Tools Mfg LLC is a leading commercial toolroom for oil and gas products, using state-of-the-art CNC and conventional machining. We specialize in precision machining and the manufacturing of drill tools for the oil and gas industry.

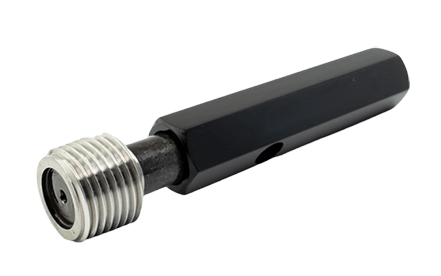

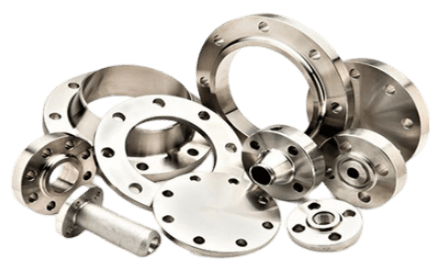

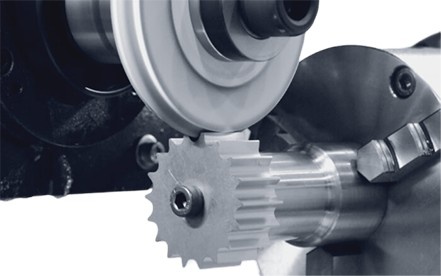

ENGINEERING PRODUCTS

Trio Tech Dies and Tools Mfg LLC is a leading commercial toolroom specializing in engineering products. Using advanced CNC and conventional machining, we produce high-quality products that meet industry standards.

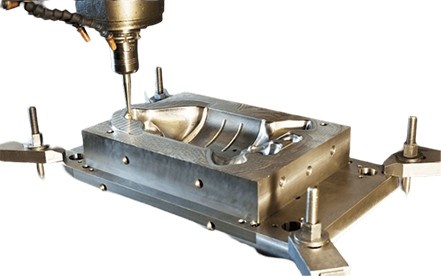

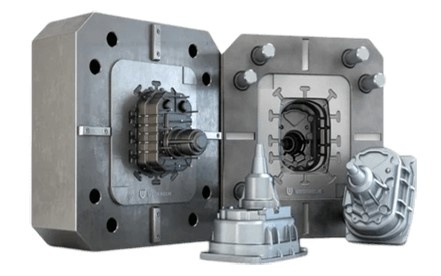

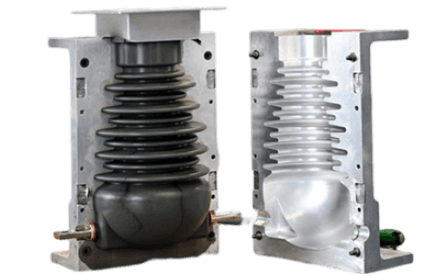

MOULDS & TOOLS PRODUCTION

Trio Tech Dies and Tools Mfg LLC is a CNC machine shop specializing in moulds and tools production. With advanced CNC machining and design software, we excel in intricate machining for automotive and aerospace industries.